Elsyca CorrosionMaster

Identify corrosion hot spots and predict corrosion rates

More infoDownload file

Elsyca CorrosionMaster

CAD based software platform for simulating the inherent corrosion susceptibility of assemblies of various substrates and/or metallic coatings

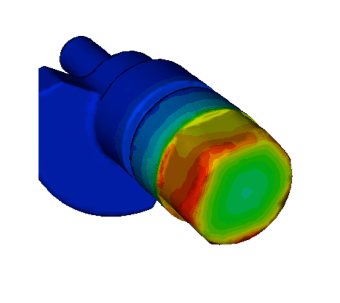

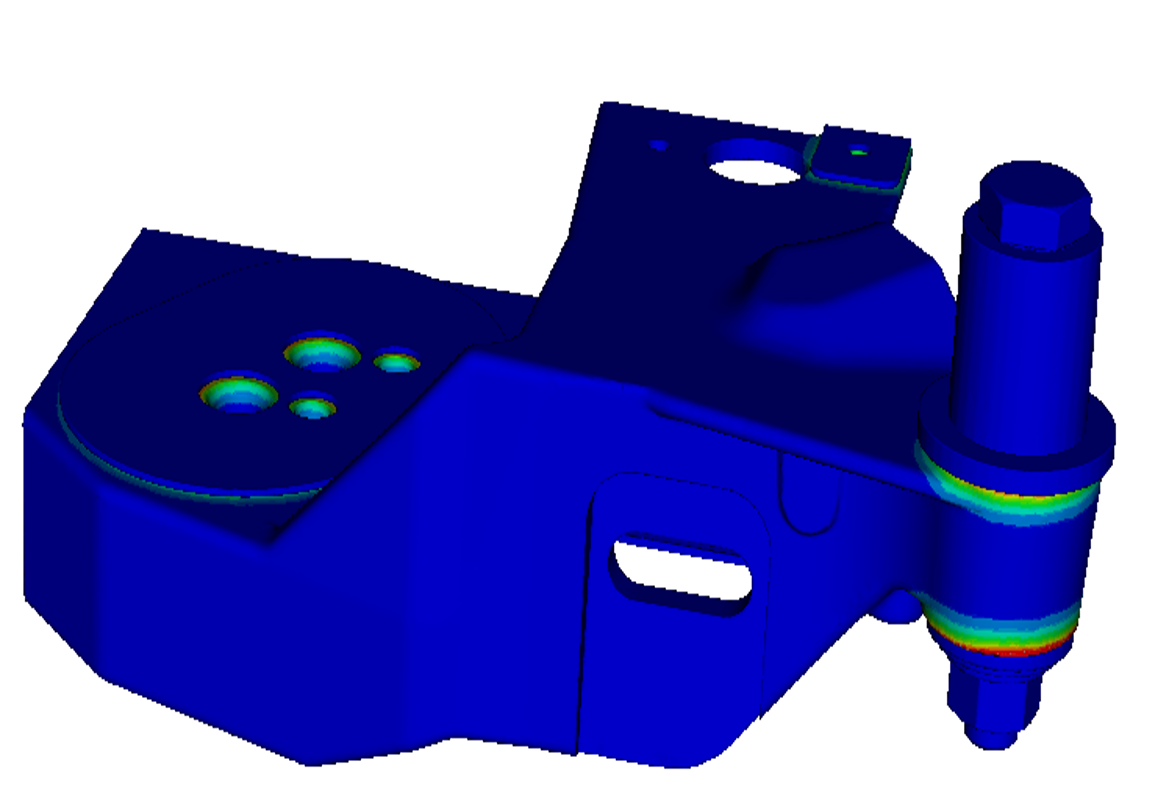

Elsyca CorrosionMaster identifies corrosion hot spots and predicts corrosion rates. The engineer can quickly evaluate design alternatives to improve the functional life, and can judge the difference in corrosion life depending on the environment in which the product will be operated (for example coastal versus inland).

Verifying your assembly inherent corrosion susceptibility

Elsyca Corrosion is not a simple look-up of galvanic potentials. The FEA-based technology solves for the potential distribution in a thin film over the surfaces of the assembly as a function of material/environment polarization characteristics.

Recently, the Elsyca CorrosionMaster platform tool was extended with the brand-new Crevice Corrosion module. When it comes to crevice corrosion, local geometrical effects start playing a role: access to oxygen is limited within the crevice, concentration changes cannot be neglected anymore, etc. Hence, the macro-scale simulation approach was extended to the level of the micro-scale.

Elsyca CorrosionMaster – Crevice Corrosion enables modeling the local characteristics within the crevice, remaining at the same time robust and fast for a quick corrosion risk assessment.

Key features

A wide range of functionalities

Import and prepare your model in just a few clicks

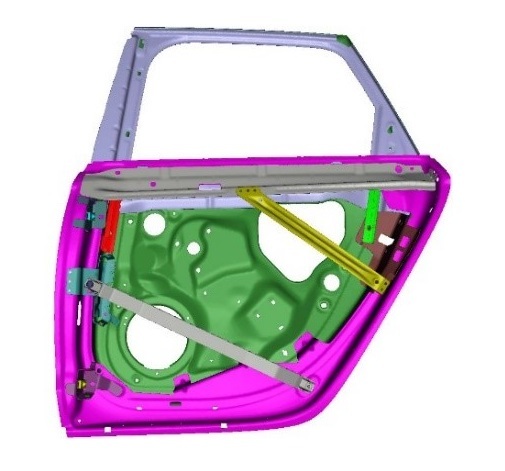

Simply export your model from your favorite CAD platform and import the STL files into Elsyca CorrosionMaster. It is indeed as simple as that!

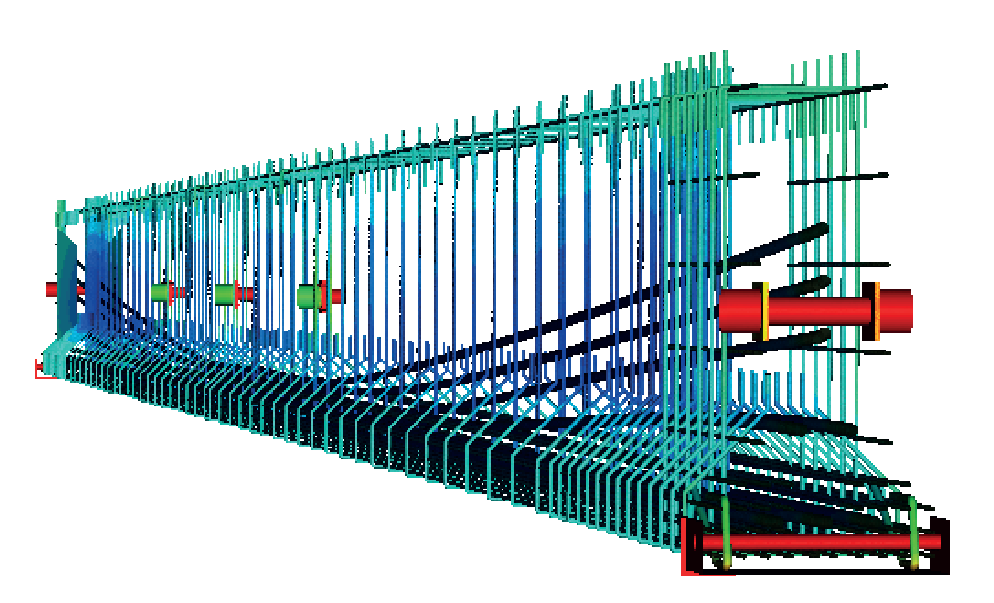

From components to full assembly

Analyze any level of complexity from components to full assembly, accurately predict and identify corrosion susceptibility of your designs

Automation

Automated high-quality meshing included – no user interaction required;

Accurate physical modeling

Allows modeling of shape change due to corrosion, supports sacrificial coatings, includes modeling of paint degradation and Crevice Corrosion module;

Lifecycle prediction

Supports time-stepping for accumulation of corrosion damage over service life;

Elsyca XPlorer compatible

Generated outputs compatible with Elsyca XPlorer, the visualization and post-processing environment that allows sharing 3D simulation results with other stakeholders.