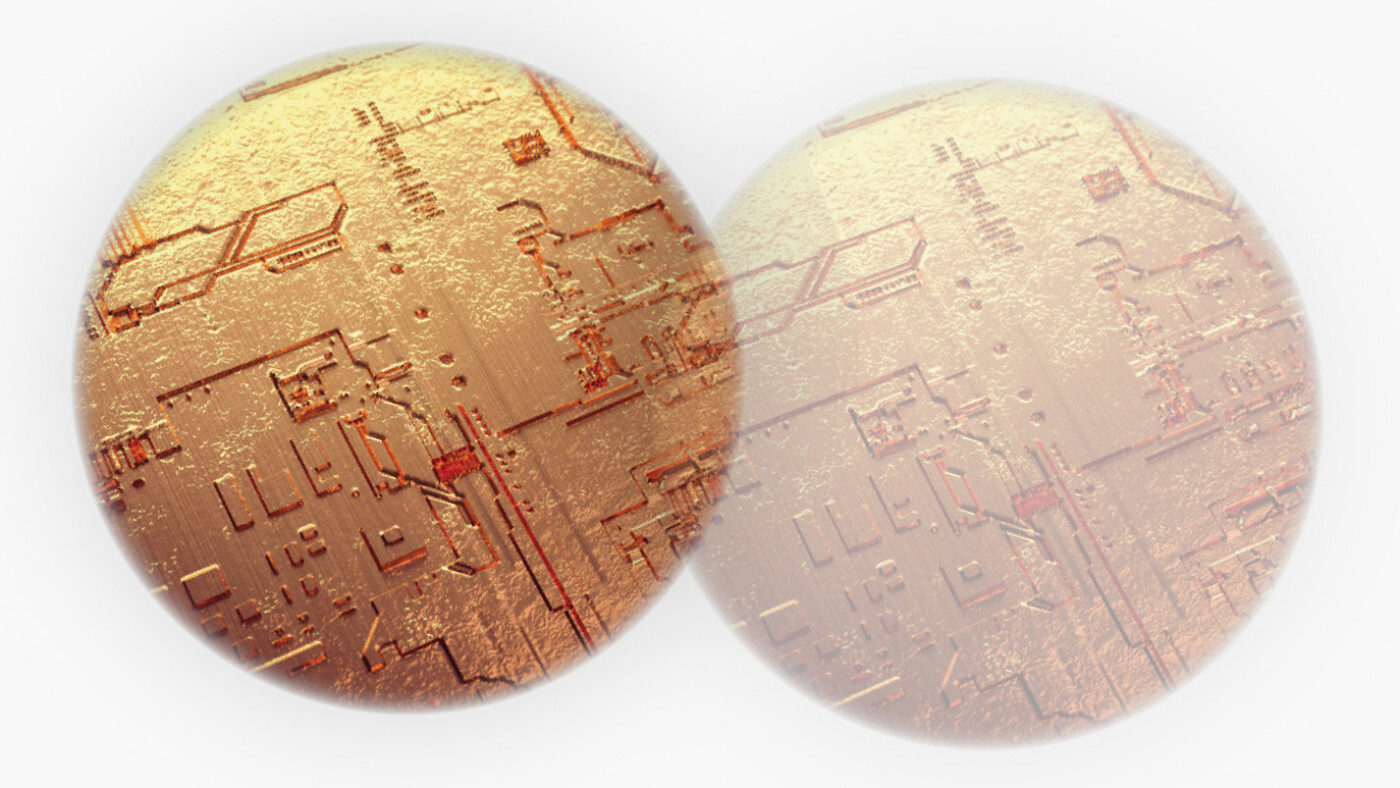

Digital twin concept in Cu electroplating processes

For better process control and superior metal finish

Plus Magazine - September 2023

Copper electroplating plays an extremely important role in PCB manufacturing and its major advantage is to reduce the ground line impedance and voltage drop. The process performance directly affects the quality of the copper layer and related mechanical properties: in acid copper plating, the challenge is to achieve proper thickness distribution and surface uniformity without unduly compromising metallurgical properties, such as percent elongation and tensile strength of the deposit. Reducing the current density can equalize the copper thickness to some extent, but leads to an inordinate increase in the overall plating time, affecting the throughput of PCBs drastically. Therefore, the proper control of the process performance and consequently, the quality of the electroplated copper layer, are both important parts of the PCB plating technique, which remains one of the challenging processes even for relatively experienced PCB factories. Thus, it seems that an upfront recognition of the plating process performance in terms of the Cu layer coverage and thickness, would add a great value to the proper process design and control. How to achieve that? Here comes the concept of a digital twin of the Cu electroplating process.

Visit external link