Revolutionizing EV Battery Tray Protection

Unveiling the Power of Computer Aided E-Coating Engineering

Overview

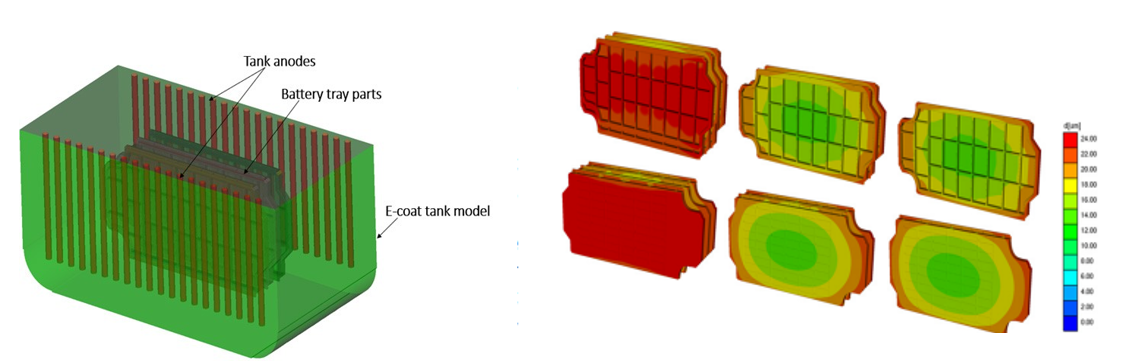

Regardless of whether they are labeled as packs, boxes, or trays, these frameworks that encompass and safeguard electric vehicle (EV) battery cells, along with their associated electrical and thermal management components, stand as one of the foremost priorities in the EV industry’s subsystem hierarchy. Enhancing the battery pack involves a multitude of decisions in manufacturing and materials, balancing mass and packaging, ensuring safety measures, and tackling structural design and engineering challenges. One of the challenges involves acquiring a proficient acid-resistant protective coating applied to battery trays and power backup systems. This coating serves the dual purpose of delivering superior electrical insulation while also resisting acidic substances effectively.

Context

With the increasing number of EVs, there is a surging need for specialized coatings and components to guarantee both functionality and safety. Simultaneously, it is imperative that these coatings do not undermine the overall performance of the EV. Given that approximately 40% of an EV’s cost comprises the battery, it becomes absolutely essential to safeguard the battery with appropriate coatings to uphold its longevity and the vehicle’s efficiency.