Design Plateability Analysis for plating-on-plastics

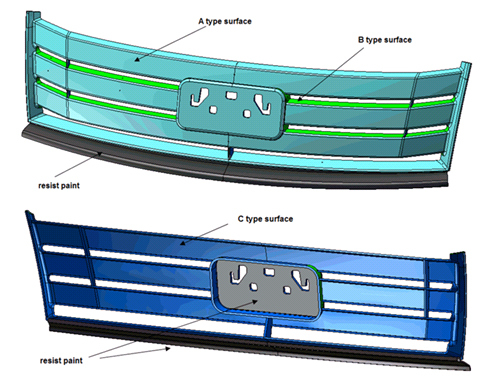

The plateability analysis of the car grille part starts by defining the different surface categories. A and B type surfaces have minimum layer thickness specifications, whereas, C type surfaces and the insulated surfaces do not.

The plateability analysis of the car grille part starts by defining the different surface categories. A and B type surfaces have minimum layer thickness specifications, whereas, C type surfaces and the insulated surfaces do not.

| Surface area [dm2] | ||||

|---|---|---|---|---|

A type surfaces | in full sight when mounted on the end product | 28.8 | ||

B type surfaces | side viewed when mounted on the end product | 2.2 | ||

C type surfaces | not visible when mounted on the end product | 29.0 | ||

| Insulated surfaces | resist painted, waxed, taped | 18.0 | ||

| Totaal | 78.0 | |||

The next step is to define a bounding box around the part that respects indicative distances to neighbour parts, tanks walls and main anodes. For each plating step the process parameters are applied (plating time and imposed current). Typically the total current to be imposed is obtained from multiplying a specified average current density value with the total A and B type surface area of the part.

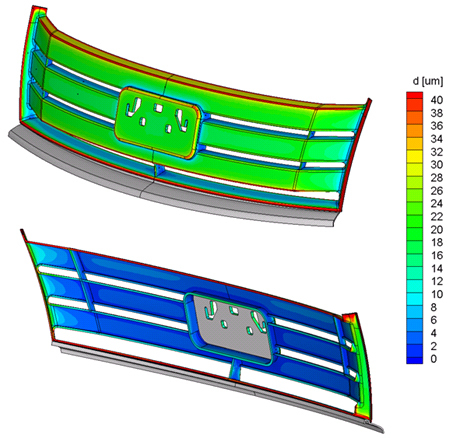

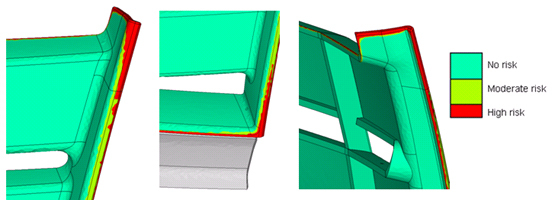

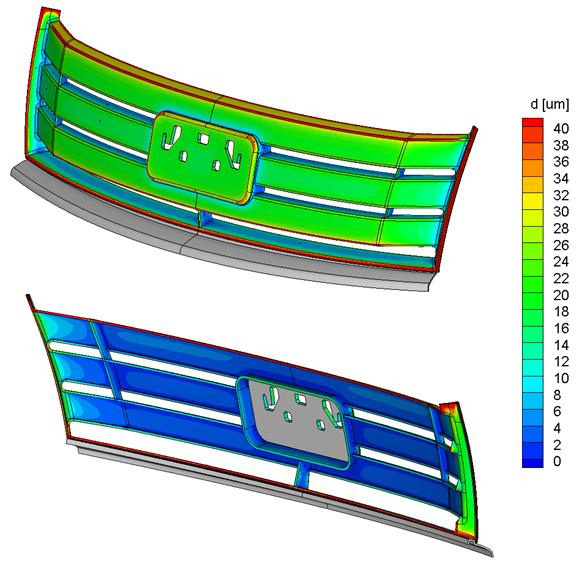

The simulation results comprise detailed colour maps of deposit thickness over the entire part and key statistics such as average deposit thickness over the A, B and C type surfaces. Additional colour plots highlight surface areas with a significant risk for layer quality issues.

The color plots below show that nickel layer thickness specifications are not met for the window areas in between the ribs of this grille part. Also, a substantial risk exists for the occurrence of nodular / dendritic deposit growth and / or chrome burn near the edge corners of the part.

The results from a plateabiltiy report are delivered to the customer in document format containing the different global result data in tabular format and color plots for all the plating steps, for example copper, nickel and chrome

Result files are also made available in numerical format through the Elsyca data server for visualisation by means of the Elsyca XPlorer viewer.

| A type surfaces | B type surfaces | C type surfaces | ||

|---|---|---|---|---|

Copper strike | 2.9 | 1.3 | 1.3 | |

Acid copper | 24.8 | 10.1 | 10.3 | |

| Semi-bright nickel | 22.3 | 8.5 | 8.4 | |

| Bright nickel | 9.0 | 3.7 | 3.6 | |

| Hexavalent chrome | 0.33 | 0.07 | 0.10 | |