Enhancing Pipeline Safety and Compliance

How Elsyca is supporting pipeline operators meet PHMSA New Requirements

Context

The U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA) has implemented a series of regulations, known as the GAS MEGA rule, to enhance the safety and reliability of natural gas pipelines in the United States. Among the three main parts of this rule, the second part that took effect on May 24, 2023, also referred to as "RIN-2”, focuses on critical aspects such as risk assessment, data integration, engineering critical assessment for dents, and management of change.

Elsyca’s unique expertise in electrochemistry and corrosion modeling and its translation into robust industrial digital twin solutions is more than ever an asset to help pipeline operators meet the PHMSA requirements and in particular the set forth by the PHMSA's second rule.

Proactive Exterior Corrosion Integrity Management:

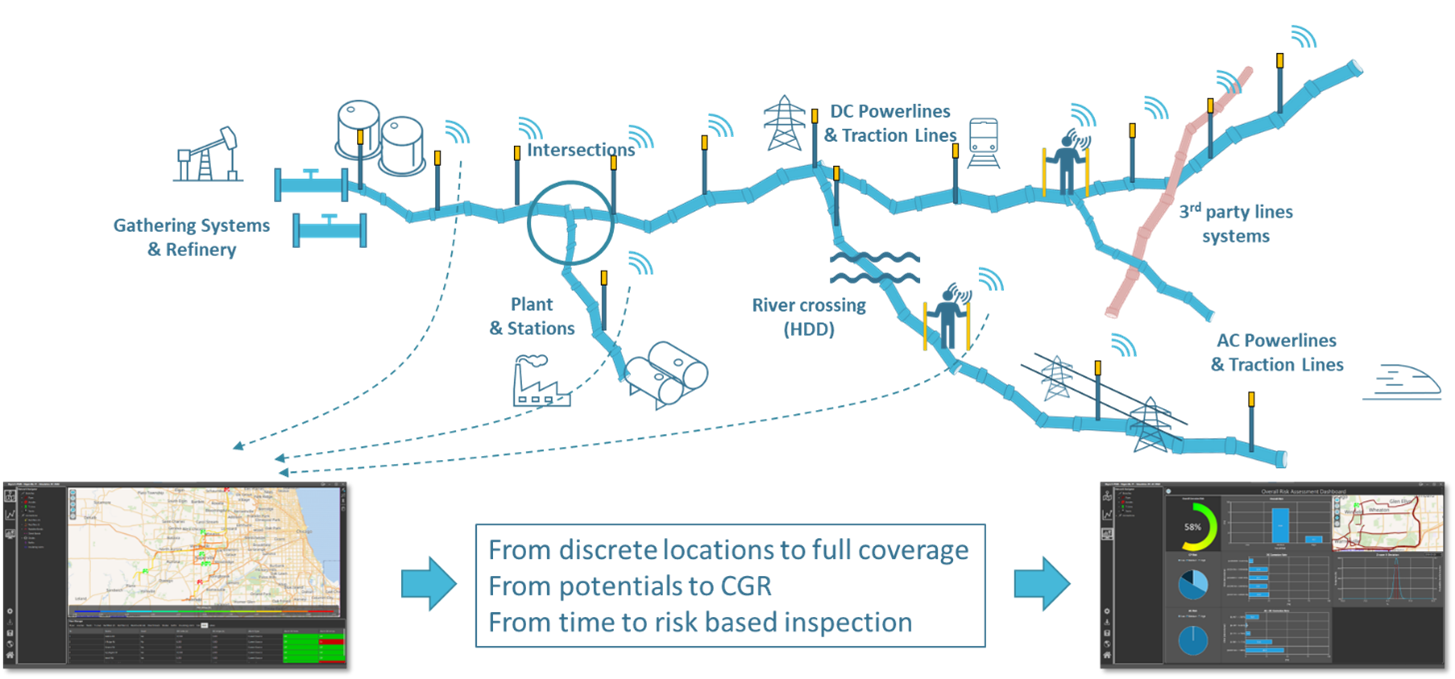

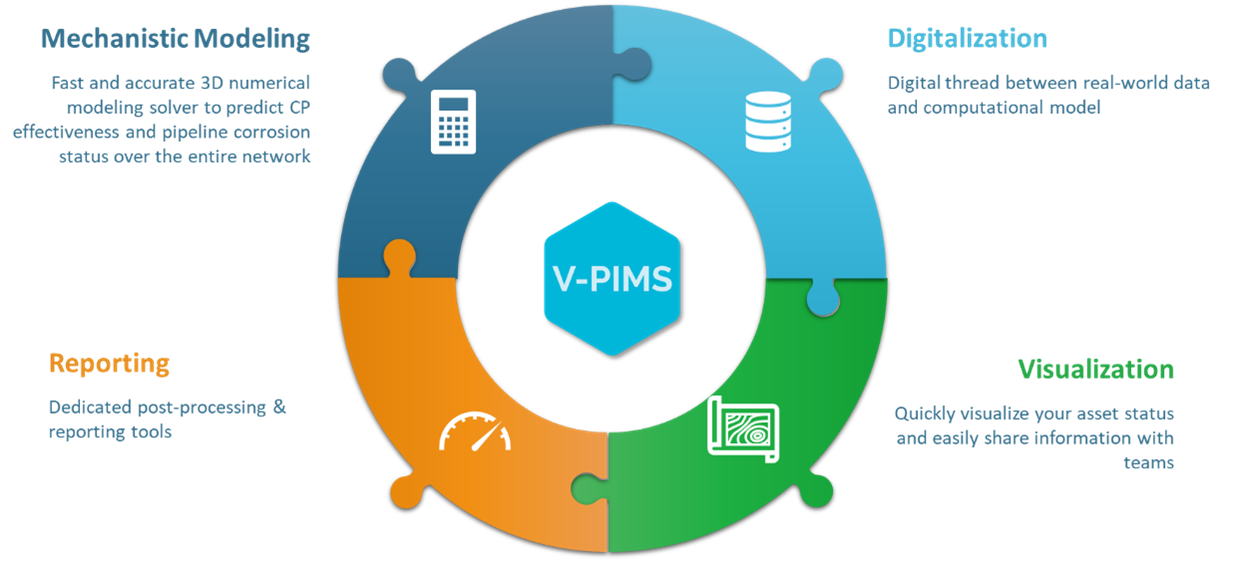

Under the second rule, pipeline operators are required to develop a proactive approach to exterior corrosion integrity management. Elsyca's unique software solutions provide valuable tools to support this objective. The outcomes of the solutions support operators in their understanding of external corrosion phenomena over their entire network.

By revealing what is happening in-between test stations or at non-piggable locations, operators can better identify and prioritize high-risk or potentially non-compliant areas, prioritize actions, and optimize corrosion control strategies. The combination of a unique mechanistic modeling approach and the ability to use existing field data and link remote monitoring units allows operators to not only continuously monitor their network but also better apprehend the effects of rectifier outages, changes in neighboring power line loads or the impact of foreign pipelines.

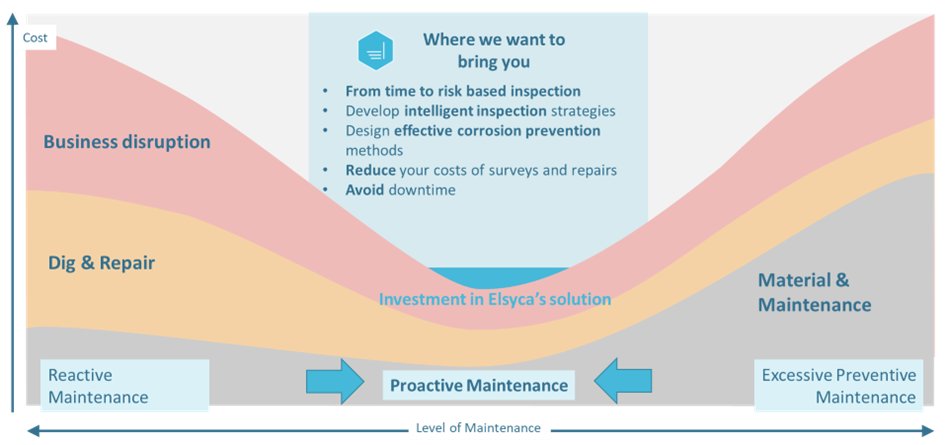

Ultimately, field inspections and the maintenance of test stations can be reduced, cost related to digs and repairs is lowered while cathodic protection system designs are improved and account for optimal DC and AC mitigation systems.

Risk Assessment and Management:

The PHMSA emphasizes the importance of conducting comprehensive risk assessments to identify and mitigate potential hazards. Elsyca's software enables pipeline operators to perform detailed risk assessments related to external corrosion by considering various factors such as pipeline characteristics, operating conditions, and environmental factors. By simulating and modeling potential failure scenarios, operators can identify critical systems, their sensitivity to integrity performance together with monitoring of corrosion growth for accurate MAOP updates.

Operators can evaluate the effects of continuous changing conditions (soil, product, AC-DC,…), and make informed decisions based on accurate and reliable data. The automatic translation of potential measurements to corrosion growth rate gives operator key indicators for a better corrosion control approach and allows the development of risk-based inspection programs in contrast to the actual costly time-based approach. ILI inspection intervals can be effectively refined and more intelligent inspection strategies developed.

Efficient Data Integration and Reporting:

Accurate data integration and reporting are essential components of compliance with the PHMSA's second rule. Elsyca's software solutions offer robust data management capabilities, allowing operators to centralize and analyze information related to pipeline external corrosion integrity.

Periodic accurate and robust evaluation of network status can be easily deployed based user requests and using Elsyca’s solution automatic gathering function. Via dedicated post-processing and reporting tools, operators can maintain traceable, verifiable, and complete records as required by the regulations. This ensures transparency and facilitates regulatory compliance during inspections and audits. The cross-department communication is enhanced and Corrosion, Integrity and Reliability teams can all benefit from the same tool.

Overall, Elsyca's digital twin solutions enables proactive maintenance that provides invaluable support to pipeline operators in meeting assessment, survey, and record-keeping requirements outlined in the Final Rule.